PDDL Tutorial¶

What is PDDL?¶

PDDL (Planning Domain Description Language) is a standard encoding language for “classical” planning.

- The components of PDDL files are:

Requirements: defining levels of abstraction in the language, e.g., “STRIPS”, temporal, probabilistic effects etc.

Types: sets of the things of interest in the world,

Objects: instances of types,

Predicates: Facts about objects that can be true or false,

Initial state of the world: before starting the planning process,

Goal: properties of the world true in goal states and achieved after the planning process,

Actions/Operators: ways of changing states of the world and going from the initial state to goal states.

- A planning task in PDDL is specified in two text files:

A domain file for requirements, types, predicates and actions,

A problem file for objects, initial state and goal specification.

Domain files are as follows:

(define (domain <domain name>)

<PDDL code for requirements>

<PDDL code for types>

<PDDL code for predicates>

<PDDL code for first action>

[...]

<PDDL code for last action>

)

where <domain name> is a string that identifies the planning domain.

Note

Many examples are available in src/test/resources/benchmarks/pddl. Domains and problems are classified by

competition year and by track

Problem files are as follows:

(define (problem <problem name>)

(:domain <domain name>)

<PDDL code for objects>

<PDDL code for initial state>

<PDDL code for goal specification>

)

- where:

<problem name>is the string that identifies the planning task, e.g. gripper with 4 balls to move.<domain name>is the planning domain name corresponding to problem file.

Note

Novices in PDDL should start by doing the A Simple Running Example: Logistics. Advanced readers can go directly to the An Industrial Use Case.

A Simple Running Example: Logistics¶

We will use the Logistics domain to illustrate how to represent a planning task in PDDL.

In logistics, there are trucks and airplanes that can move packages between different airports and cities. We assume that in the initial state there is a truck in Paris airport. An airplane and two packages are in London airport. Paris has two places : south and north. The goal is to have one package in the north location and the other one in the south location.

Todo

First, create two text files respectively called logistics.pddl and problem.pddl and copy

paste the PDDL code fragment given step by step in theses files. You can choose whatever text

editor you want

Note

Remember that PDDL requires two files: 1. A domain file for requirements, types, predicates and actions, 2. A problem file for objects, initial state and goal specification.

Defining the Domain¶

- Let start by defining in the file

logistics.pddlthe domain and its components : the requirements,

the types,

the predicates,

the actions or the operators.

First, we have to define the name of the domain:

In PDDL, we write :

(define (domain logistics)

Requirements¶

- The requirements for this logistics example are:

strips : the actions will only use positive preconditions (predicates that must be true in the current state to trigger actions) and deterministic effects (effects that necessarily follow action triggering). Nothing else is allowed.

typing : we will use “types” like in OO programming to represent sets of objects in the world.

In PDDL, we write :

(:requirements :strips :typing)

Types¶

- We will use the following types:

Places, cities and physical objects are considered as objects,

Packages and vehicles are physical objects,

Trucks and airplanes are vehicles,

Airports and locations are places.

In PDDL, we write:

(:types city place physobj - object

package vehicle - physobj

truck airplane - vehicle

airport location - place

)

Predicates¶

- We will use the following predicates:

in-city(loc, city) - true iff a place loc is in the city city

at(obj, loc) - true iff a physical object obj is at place loc

in(pkg, veh) - true iff the a package pkg is in a vehicle veh

In PDDL, question marks are used for variables:

(:predicates (in-city ?loc - place ?city - city)

(at ?obj - physobj ?loc - place)

(in ?pkg - package ?veh - vehicle)

)

Operators¶

We are going to define the operators of the actions of the logistics domain, i.e., the means to change the states of the world. The domains has 5 operators: load-truck, load-airplaine, unload-truck, unload-airplane, drive-truck and fly-aiplane.

Note

In this tutorial, we will use indifferently the words “action” and “operator” (though in planning community, actions are ground operators, i.e., operator where variables are replaced by constants).

Load Truck Operator

For instance, in the logistics domain, a truck can be loaded… And to load a truck, we need a package pkg and a truck truck at a place loc. To load pkg in truck, these two objects must be at the same place loc. The effects of loading pkg in truck are that in(pkg, truck) becomes true and at(pkg, loc) becomes false. Any other fact in the current state does not change:

(:action load-truck

:parameters (?pkg - package ?truck - truck ?loc - place)

:precondition (and (at ?truck ?loc) (at ?pkg ?loc))

:effect (and (not (at ?pkg ?loc)) (in ?pkg ?truck))

)

Load Airplane Operator

- Action/Operator :

Description : Load a package pkg in an airplane airplane at a place loc,

Precondition : at(pkg, loc) and at(airplane, loc) must be true,

Effect : in(pkg, airplane) becomes true and at(airplane, loc) becomes false.

In PDDL:

(:action load-airplane

:parameters (?pkg - package ?airplane - airplane ?loc - place)

:precondition (and (at ?pkg ?loc) (at ?airplane ?loc))

:effect (and (not (at ?pkg ?loc)) (in ?pkg ?airplane))

)

Unload Truck Operator

- Action/Operator :

Description : Unload a package pkg in a truck truck at a place loc,

Precondition : in(pkg, truck) and at(truc, loc) must be true,

Effect : at(pkg, loc) becomes true and in(pkg, truck) becomes false.

In PDDL:

(:action unload-truck

:parameters (?pkg - package ?truck - truck ?loc - place)

:precondition (and (at ?truck ?loc) (in ?pkg ?truck))

:effect (and (not (in ?pkg ?truck)) (at ?pkg ?loc))

)

Unload Airplane Operator

- Action/Operator :

Description : Unload a package pkg in an airplane airplane at a place loc,

Precondition : in(pkg, airplane) and at(airplane, loc) must be true,

Effect : at(pkg, loc) becomes true and in(pkg, airplane) becomes false.

In PDDL:

(:action unload-airplane

:parameters (?pkg - package ?airplane - airplane ?loc - place)

:precondition (and (in ?pkg ?airplane) (at ?airplane ?loc))

:effect (and (not (in ?pkg ?airplane)) (at ?pkg ?loc))

)

Fly-airplane Operator

- Action/Operator :

Description : Fly airplane pkg from a location loc-from to a location loc-to,

Precondition : at(pkg, loc-from) must be true,

Effect : at(pkg, loc-to) becomes true and at(p, loc-from) becomes false.

In PDDL:

(:action fly-airplane

:parameters (?airplane - airplane ?loc-from - airport ?loc-to - airport)

:precondition (at ?airplane ?loc-from)

:effect (and (not (at ?airplane ?loc-from)) (at ?airplane ?loc-to))

)

Drive-truck Operator

- Action/Operator :

Description : Drive truck truck from a location loc-from to a location loc-to,

Precondition : at(truck, loc-from) must be true,

Effect : at(truck, loc-to) becomes true and at(truck, loc-from) becomes false.

In PDDL:

(:action drive-truck

:parameters (?truck - truck ?loc-from - place ?loc-to - place ?city - city)

:precondition (and (at ?truck ?loc-from) (in-city ?loc-from ?city) (in-city ?loc-to ?city))

:effect (and (not (at ?truck ?loc-from)) (at ?truck ?loc-to))

)

Note

Action preconditions and effects can be more complicated than seen so far. They can be universally or existentially quantified using PDDL statement of the form

(forall (?v1 ... ?vn) <effect >). In that case, specific requirements must be used, for instance:adl.They can be conditional :

(when <condition > <effect >)Action They can have costs, duration, time constraints etc.

Defining the Problem¶

- Now, let define in the file

problem.pddla simple problem and its components : the objects,

the initial state,

the goal to reach.

First, we have to define the name of the problem and indicate the domain associated with this problem:

In PDDL, we write :

(define (problem p01)

(:domain logistics)

Objects¶

- In this example, we use the following objects:

A Truck : truck

An airplane: airplane

Two airports : cdg, lhr

Two places : north, south

Two cities : london, paris

Two packages : p1, p2

In PDDL, we write:

(:objects plane - airplane

truck - truck

cdg lhr - airport

south north - location

paris london - city

p1 p2 - package

)

Note

The types of the object can be only the types defined in the domain or the type object.

Initial State¶

The initial state is a set of ground predicates. A predicate is ground iff all the variables are bound to objects. The ground predicates in the initial state represent true facts in this state. Any fact that is not represented in a state is false: In our case:

(:init (in-city cdg paris)

(in-city lhr london)

(in-city north paris)

(in-city south paris)

(at plane lhr)

(at truck cdg)

(at p1 lhr)

(at p2 lhr)

)

Goal Description¶

The goal is to have at(p1, north) and at(p2, south) in the final state (no matter the truth value of the other predicates). In PDDL, we write:

(:goal (and (at p1 north)

(at p2 south))

)

Note

If you have not completed the files as you go, the domain logistics.pddl file

and the problem problem.pddl file can be downloaded directly.

Todo

Run HSP planner on the logistics domain and the problem.

Running the logistics example¶

The procedure to run the logistic domain and problem with HSP planner of the library is given below:

Open a terminal

Create a directory called PDDL4J:

$ mkdir pddl4j

Go to the directory:

$ cd pddl4j

Download the binary of last release (X.X.X is the number of release - see Download.

$ wget http://pddl4j.imag.fr/repository/pddl4j/binaries/pddl4j-4.0.0.jar5. Move the domain file

logistics.pddlpreviously created or download it in thepdd4jdirectory.6. Move the domain file

problem.pddlpreviously created or download it in thepdd4jdirectory.

Test the example:

$ java -jar pddl4j-X.X.jar -server -Xms2048m -Xmx2048m -p HSP -o logistics.pddl -f problem.pddl

- The JVM (Java Virtual Machine) arguments:

-jarspecified the executable jar of the library.

-XMSand-XMXallow to set the maximum heap size and the maximum memory size that can be used by the JVMThe result will be:

parsing domain file "logistics.pddl" done successfully parsing problem file "problem.pddl" done successfully encoding problem done successfully (28 ops, 17 facts) found plan as follows: 00: ( loadd-airplane p1 plane lhr) [1] 01: ( loadd-airplane p2 plane lhr) [1] 02: ( fly-airplane plane lhr cdg) [1] 03: ( unload-airplane p1 plane cdg) [1] 04: ( unload-airplane p2 plane cdg) [1] 05: ( load-truck p1 truck cdg) [1] 06: ( load-truck p2 truck cdg) [1] 07: ( drive-truck truck cdg south paris) [1] 08: ( unload-truck p2 truck south) [1] 09: (drive-truck truck south north paris) [1] 10: ( unload-truck p1 truck north) [1] plan total cost: 11,00 time spent: 0,09 seconds parsing 0,03 seconds encoding 0,01 seconds searching 0,13 seconds total time

An Industrial Use Case¶

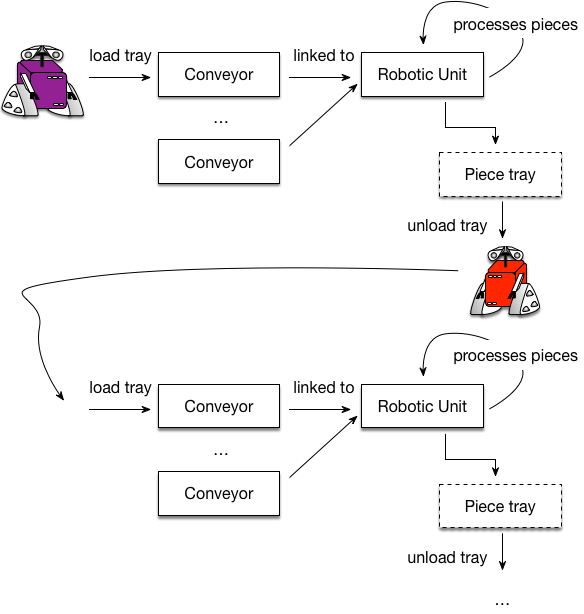

This is a real case that we tackled for a manufacturing company. This company devises supply chains to make pieces of medical equipments. A supply chain consists of independent robotized units/cells, which realize specific operations on the pieces: cleaning, checking, marking, assembling etc. The pieces are put on trays, and mobile robots are programmed to take and to transport the trays between the different units. The image below illustrates this process:

There are different symbolType of pieces at the beginning of the supply chain. A tray contains only one symbolType of pieces, and, each piece undergoes a sequence of operations from the beginning to the end of the supply chain. At the beginning of the supply chain, a unit is used to store all the trays. The units can have several inputs named “conveyors”. The conveyors and the units are specific to a set of pieces: pieces are admissible to identified conveyors and units. Initially, every processing (unit loading/unloading, robot movements etc.) was hard-coded in a database by human operators. Automated planning is now used to optimize unit/robot scheduling and to increase production efficiency.

Todo

Try to write your own domain file for this problem.

Before reading the proposed solution below, write a simple problem file and test your domain. For instance, a simple problem is one type of pieces, a single tray, robot and conveyor; two units, a stocker storing this tray at the initial state and a processing unit. The goal is for the unit to perform three operations (op10 > op20 > op30) on the tray.

Defining the Domain¶

Requirements¶

Let start by creating the domain file. For instance, rsc-domain.pddl write the following PDDL to give a name to

this domain and specify the requirements of the domain.

(define (domain robotic-manufactoring)

(:requirements :strips :typing)

Types¶

Then, define the set of objects (types) that will be used in this domain. Quite obviously, we will have the types robot (mobile robots), conveyor, unit, piece, etc.

(:types

robot - agent

conveyor unit - location

piece operation tray - object

)

Constants¶

We also declare a dummy operation called stop as a constant of the domain which will be used in one action:

Predicates¶

Note

- Now it is time to think to a model for the domain. It is based on the following ideas:

Producer/consumer: the trays are resources consumed by the conveyors and produced by the units. A “one-to-many” relation is created between each unit and the conveyors. A tuple conveyors/unit is like a (Petri Net) “machine” that consumes and produces trays. The conveyors are the inputs and the unit is the output. Each input/output’s capacity is one,

Operation stacks: each tray is associated to a stack of operations that have to be performed on the pieces of the tray. The last operation of the stack is always _stop_. Each time a machine consumes a tray, the associated stack is pulled,

Goal: to empty all the stacks by connecting the machines with robots transporting trays from units (outputs) to conveyors (inputs). The capacity of the robots is one.

Here is the vocabulary (“predicates”) that will be used by the actions:

(:predicates

;;robot

(robot_available ?robot - robot)

;; is the robot available? capacity is one

(robot_at ?robot - robot ?l - location)

;; location of a robot. Either a conveyor or a unit

;;conveyor

(conveyor_accepted_piece ?piece - piece ?conv - conveyor)

;; constraint on admissible pieces

(conveyor_available ?conv - conveyor)

;; is the conveyor available? capacity is one

(conveyor_unit ?conv - conveyor ?unit - unit)

;; "one-to-many" relation between units and conveyors

;;unit

(unit_accepted_piece ?piece - piece ?unit - unit)

;; constraint on admissible pieces

(unit_available ?unit - unit)

;; is the unit available? unit capacity is one

(unit_operation ?op - operation ?unit - unit)

;; operation provided by the unit

;;tray

(tray_on_unit ?tray - tray ?unit - unit)

;; the tray is in the unit

(tray_on_conv ?tray - tray ?conv - conveyor)

;; the tray is input into the conveyor

(tray_on_robot ?tray - tray ?robot - robot)

;; the robot is at the tray

(tray_completed ?tray - tray)

;; all the scheduled operations are completed

;;piece

(piece_on ?piece - piece ?tray - tray)

;; "one-to-one" relation: trays contain only one type of pieces

;;stack of operations

(start ?op - operation ?tray - tray)

;; ?op is on top of the stack.

;; The stack has a one-to-one relation with the tray (same id)

(todo ?opontop - operation ?nextop - operation ?tray - tray)

;; linked list of operations: ?nextop follows ?opontop. Last operation is stop

)

For instance, in the problem file, you can now specify an initial state beginning by:

(start op10 tray32)

(todo op10 op20 tray32)

(todo op20 op30 tray32)

(todo op30 stop tray32)

This means that the sequence op10, op20, op30 of operations is scheduled on tray32.

Likewise,

(conveyor_unit conv1 unit1)

(conveyor_unit conv2 unit1)

means that unit1 has two inputs conv1 and conv2.

Operators¶

The new step is to define all the actions. For this domain, we will need 6 actions:

(:action pickup_tray_on_unit

:parameters (?robot - robot ?unit - unit ?tray - tray)

:precondition (and (robot_available ?robot)

(robot_at ?robot ?unit)

(tray_on_unit ?tray ?unit)

)

:effect (and (not (tray_on_unit ?tray ?unit))

(not (robot_available ?robot))

(tray_on_robot ?tray ?robot)

(unit_available ?unit)

)

)

Action pickup_tray_on_unit allows a robot to pickup a tray on a unit provided the robot is available and located at this unit. The effects are that the tray is no more on the unit, the tray is on the robot and the robot is not available to pickup another tray. The unit becomes available to process another tray.

(:action drop_tray_on_conveyor

:parameters (?robot - robot ?conv - conveyor ?tray - tray ?piece - piece)

:precondition (and (conveyor_available ?conv)

(robot_at ?robot ?conv)

(tray_on_robot ?tray ?robot)

(conveyor_accepted_piece ?piece ?conv)

(piece_on ?piece ?tray)

)

:effect (and (not (conveyor_available ?conv))

(not (tray_on_robot ?tray ?robot))

(tray_on_conv ?tray ?conv)

(robot_available ?robot))

)

Action drop_tray_on_conveyor is the counterpart of pickup_tray_on_unit. It allows a robot to put a tray on a conveyor. The preconditions are that the robot and the conveyor are in the same place, the conveyor is available and it accepts the same type of pieces than the tray. The effects are that the conveyor is no more available, the tray is no more on the robot (it is on the conveyor) and the robot is now available.

(:action robot_move

:parameters (?robot - robot ?from - location ?to - location)

:precondition (and (robot_at ?robot ?from))

:effect (and (robot_at ?robot ?to)

(not (robot_at ?robot ?from))

)

)

Action robot_move is trivial: it moves a robot from location ?from$ to location $?to. Locations are either a conveyor or a unit (see :types keyword).

(:action conveyor_load_tray_in_unit

:parameters (?conv - conveyor ?unit - unit ?tray - tray ?piece - piece)

:precondition (and (unit_available ?unit)

(conveyor_unit ?conv ?unit)

(unit_accepted_piece ?piece ?unit)

(piece_on ?piece ?tray)

(tray_on_conv ?tray ?conv)

)

:effect (and (not (tray_on_conv ?tray ?conv))

(not (unit_available ?unit))

(tray_on_unit ?tray ?unit))

)

Action conveyor_load_tray_in_unit consumes a tray that is loaded on a conveyor linked to a unit provided the pieces of the tray are accepted by this unit. As a consequence, the tray is no more one the conveyor, the unit is not available and the tray is on the unit, ready for processing.

(:action unit_execute_operation

:parameters (?unit - unit ?top - operation ?next - operation ?tray - tray)

:precondition (and (unit_operation ?top ?unit)

(tray_on_unit ?tray ?unit)

(start ?top ?tray)

(todo ?top ?next ?tray)

)

:effect (and (start ?next ?tray)

(not (todo ?top ?next ?tray))

(not (start ?top ?tray))

)

)

Action unit_execute_operation applies the operation pending on top of the tray’s stack. The preconditions are that the unit is able to perform this operation, the tray is in the unit and this operation operation is on top of the stack. The effects are that the operation is pulled from the stack and the next operation becomes the top of the stack.

(:action tray_completed

:parameters (?op - operation ?tray - tray ?unit - unit)

:precondition (and (start stop ?tray)

(tray_on_unit ?tray ?unit)

)

:effect (and (tray_completed ?tray)

(unit_available ?unit)

(not (tray_on_unit ?tray ?unit)))

)

Action tray_completed is a dummy action which purpose is to check that all the scheduled operations on a tray have been done (stop operation on top of the tray’s stack). It is used to build a goal state and to terminate the planning procedure for a given tray. Here we suppose that an operator picks up the tray once all the operations have been done and the unit becomes available to process another tray.

Defining the problem¶

Let start by creating the problem file, e.g., rsc_problem_easy.pddl. The problem we wish to define is a simple problem with one

type of pieces, a single tray, robot and conveyor; two units, a stocker storing this tray at the initial state and a

processing unit. The goal is for the unit to perform three operations (op10 > op20 > op30) on the tray.

Objects¶

Hence, the types and objects are as follows:

(:objects

unit1 stocker - unit

conv1 - conveyor

robot1 - robot

tray1 - tray

piece1 - piece

op10 op20 op30 - operation

)

Initial State¶

This snippet of code is the initial state:

(:init

;; Operation schedule

(start op10 tray1)

(todo op10 op20 tray1)

(todo op20 op30 tray1)

(todo op30 stop tray1)

;; Initiate pieces on tray

(piece_on piece1 tray1)

;; At the beginning, tray1 is on the stocker

(tray_on_unit tray1 stocker)

;; Initiate robot

(robot_at robot1 stocker)

(robot_available robot1)

;; Initiate conveyor

(conveyor_unit conv1 unit1)

;; Setup unit

(unit_accepted_piece piece1 unit1)

(unit_accepted_piece piece1 stocker)

(unit_operation op10 unit1)

(unit_operation op20 unit1)

(unit_operation op30 unit1)

;; Unit1 is ready

(unit_available unit1)

;; Setup conveyor

(conveyor_accepted_piece piece1 conv1)

(conveyor_available conv1)

;; Setup robot

(robot_available robot1)

)

Goal Description¶

The goal is simply the completion of tray1:

(:goal

(and (tray_completed tray1))

)

- Complete files can be downloaded here:

Note

To go further, we recommend the reader to refer to this good resource on PDDL